Articles

Back to articles

6 x 10ft High-Mass Wood-Fired Commercial Bread Oven

This 72” x 121.5” net baking area high-mass commercial bread oven was built for the Humble Bread bakery, located in the Prince Edward County, Ontario. http://www.humblebread.com/ My design decisions for this oven were inspired by low-vault ovens built by John Fisher in Sweden http://www.fishermureri.se and also influenced in part by what I have seen on pictures of French traditional guilard-style ovens Antoine Guerlain brought from his trip to France with Dave Bauer http://farmandsparrow.com/ . One of the main features is that the oven was designed for use of canvas bread loaders (device enabling baker to load and unload several rows of bread at once in matter of seconds with very little effort). The doors system for the oven was designed and built for this purpose by Turtlerock Masonry Heat http://www.turtlerockheat.com/.

The oven features:

- - a very low vault of 12" maximum height and no height reduction, but instead two main exits: one in each back corner right in the vault (natural reduction of 2" due to vault rise).

- - a firing door at the back of the oven. We have decided that keeping all wood dirt out of the bakery is a good idea and bakery plan allowed it. I made another exit above the firing door simply to have firing door as high as possible while avoiding spillage when loading wood. This central exit has a dropped in stainless pipe (a-la bagel oven chimney exit) to be flush with top of the firing door just to avoid venting the hottest gases out when firing. This way there is no spillage, but the hottest gases do not escape. Each of three exits has a dedicated sliding damper just above, right on top of the vault. The exits, therefore, are only shallow niches in the vault, so no large space of an open smoke chamber above. All exits come into a single smoke chamber that can potentially have additional chimney damper at the base of the chimney to avoid circulation in the chimney, but it was not installed in this case. With two main exits, plus central exit, with separate dampers, there is ability to control draft and firing and have some control over direction of the gas flow inside.

- - a triple layer jack arch with a reinforced bond beam over the main opening. I think the strongest solution possible... Also,

- - a continuous expansion joint John Fisher’s style with staggered side joints in walls and in the vault at the middle, plus expansion joint in the upper brick layer in the vault at the ends of the vault.

- - Thickness of oven walls and vault is 9”, hearth is 10".

- - The oven sits on 6" of insulation boards: super-insulated from the bottom as well.

- - Very strong I-beam harness with side supports.

- - The oven is insulated with ceramic wool/mineral wool/aluminum foil in multiple layers to the total of 11”+;

- - Reclaimed brick from a demolished local church facing on front, cement board over metal studs everywhere else.

- - Shallow and deep mass thermocouples in the hearth and the vault connected to a reader. Total number of thermocouples: 10pc.

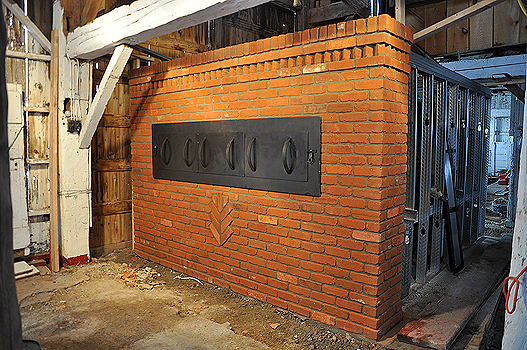

Finished oven. Baking Door insert is on.

The baking doors are thin stainless steel spring-loaded sheets on a steel frame.

They are flipped down automatically by the bread loader when it is pushed into the oven.

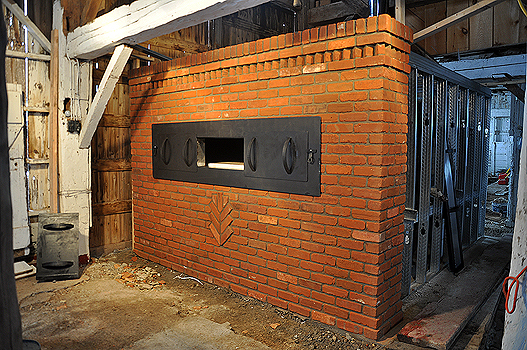

Door insert is off, replaced with insulated plugs for use

during firing and when oven is not in use.

Another view with insulated plugs.

Central plug is removed.

Insulated plugs are removed, showing the full width oven opening.

Finished oven core.

Jack arches with the bond beam, steel harness and copper tube

conduits for the thermocouples are visible.

Looking in through the firing door.

Looking in through the loading opening.

Two exits in the sides of the vault are visible.

Wheat stock brick detail at the front of the oven.

This picture is with the owners.

Left to right: Matthew Froud, Stovemaster’s mason, Natalie Normand

and Henry Willis, Sergei Kuznetsov – another Stovemaster’s mason and myself.

Henry, the owner and baker, is using the oven now to bake twice a week to sell his bread at farmers markets. At the current moment, he is using the oven for fraction of its full capacity of up to 800 loaves of bread from single firing, baking only between 150-250 loaves on a typical bake day. Henry reports that he does not steam the oven even when he is not packing the oven tight with the loaves. He said he tried steaming but it didn’t result in any noticeable improvement and he was happy with the results without steaming. You can judge by looking at pictures of his bread attached below. Henry’s specialty is naturally leavened (no commercial yeast) rye-based breads.

Henry also reports that he practically doesn’t have to move bread, indicating very even heat. The area in front of the loading doors seems to bake ok, without being noticeably cooler.

The oven is reported to keep the heat extremely well. At the end of a typical firing (which can last anywhere from 4 to 8 hours, depending on technique and starting temperatures) temperatures are 850F on the hottest of the probes (shallow mass) and 550F at the coolest (deep mass).

After the oven is left to equalize heat for a few hours, temperatures even out at about 700F.

It has been reported that if left at this stage to sit with insulated plug doors for 24 to 30(!) hours, the oven is still at 620F plus-minus 20F all throughout the thermocouples!

It should be noted, that there is no need to tend to fire continuously if the oven is loaded for firing properly and with good, dry firewood. It is possible to load practically entire amount of wood at once and set a proper burn, allowing it to consume all firewood at a steady pace over several hours without human intervention. Loading the firewood and cleaning at the end of firing are, basically, the only times when human presence is needed. The burn can be regulated, using three dampers, connecting the baking chamber with the smoke chamber.

Alex Chernov

October 2011.

|